Metal Powder Conveying Equipment Manufacturer Unveils Automated, Closed-Loop Systems for 3D Printing at Scale

Volkmann Ensures Non-Stop Flow of Metal Powder for Non-Stop Printing

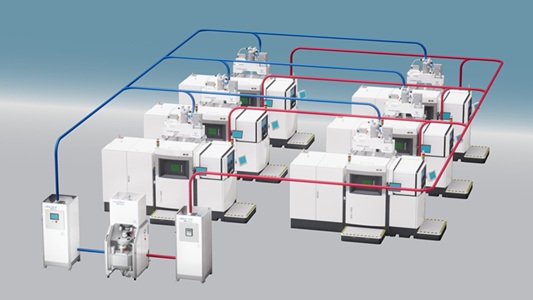

Bristol, PA: Metal powder conveying equipment manufacturer Volkmann USA, Bristol, PA, unveiled fully automated, closed-loop metal powder management systems for high volume additive manufacturing operations. Suitable for seamless integration with 3D printers from all printer manufacturers, the central metal powder management systems provide precise control over the transfer and loading of metal powder from storage into multiple 3D printers; part depowdering and cleaning; and the capture, sieving, and transfer of excess powder to storage or back for reprocessing. Replacing manual operations with a scalable approach, the Volkmann closed-loop systems ensure an uninterrupted flow of metal powder to hundreds of printers simultaneously to maximize uptime and reduce the cost per part.

Running unattended 24/7 and controlled remotely, the metal powder management systems operate as a fully enclosed, sealed circuit that creates a barrier between the material and the work environment throughout every stage of the process. Concerns about metal powder contamination, nuisance dust, and worker safety are eliminated.

The proprietary, closed-loop metal powder systems are proven effective with tungsten, cobalt, silver powder, iron, stainless steel, alumina, nickel chrome, copper, titanium, and other metallic powders and may be customized with inline vacuum drying, buffer storage, and other accessories. Inert gas systems are also available.

Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services